ຮູບແບບອີເມວຜິດພາດ

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

ຂ່າວ

Daily Care and Maintenance of 850 Machining Center

850 vertical machining center is a high-quality, high-precision, high-performance machine tool processing equipment, which can continuously complete 2D and 3D curved surfaces, as well as drilling, expanding, reaming and other processing of inclined surfaces in one clamping. It is generally used in the processing of parts in the automotive, mold, aviation and military industries.

Features of Machining Center

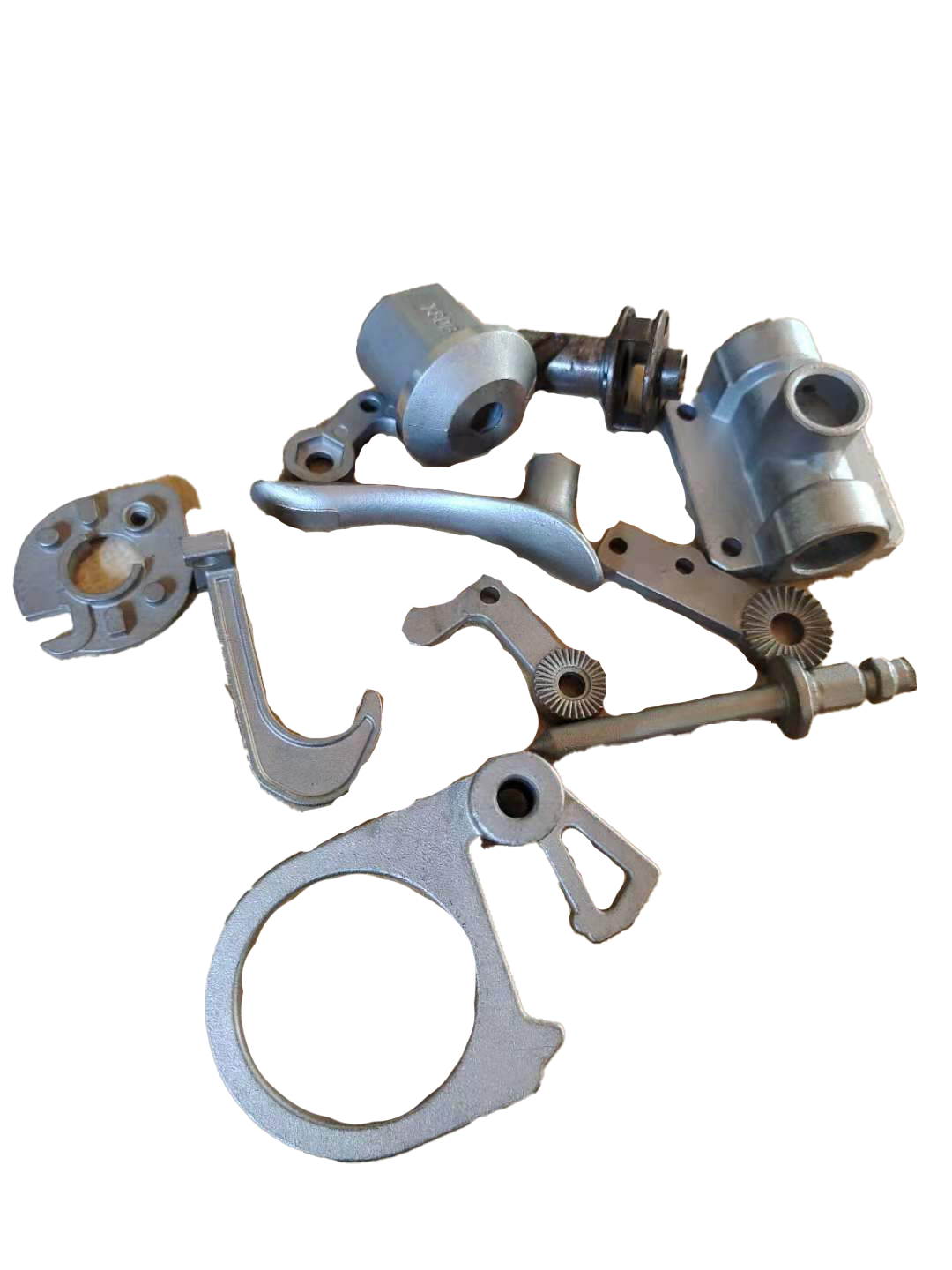

The 850 machining center is a fully enclosed vertical machining center with three axes of X, Y, and Z servo direct connection control. All three axes are steel ball rolling linear guide rails. The spindle is driven by a servo motor through a synchronous belt. It can realize one-time clamping of various discs, plates, shells, cams, molds and other complex parts, and can complete drilling, milling, boring, expanding, reaming, rigid tapping and other processes. The production of small and medium-sized products can meet the processing of complex and high-precision parts. It can be equipped with a fourth rotation axis to meet the processing requirements of special parts.

Due to the high cost of machining centers, in order to maximize the role of equipment production, reduce production costs, and improve production efficiency, it is necessary to learn to maintain and maintain the processing equipment in daily operations to avoid unnecessary wear and tear, thereby extending the equipment. service life. The following will introduce the daily maintenance measures of the 850 machining center.

Daily care and maintenance of 850 machining center

Keep your equipment clean inside and out

After the machining center completes the operation, the sliding surfaces, lead screws, racks, oil holes and other parts are prone to residual oil stains. Clean them up and check whether there is oil leakage or air leakage in each part. The surrounding debris, etc., should also be cleaned up to keep the surroundings of the equipment clean and tidy.

Equipment accessories, workpieces, etc. are placed regularly

During the processing operation, in addition to the safe and stable placement of the processed parts, other accessory tools should also be placed properly, especially the pipes, lines and other components, and should be placed in an orderly manner to avoid chaotic entanglement and affect the entire processing process.

Refuel or change oil regularly to maintain equipment lubrication

Whether the equipment is lubricated or not will directly affect the processing efficiency, so in the daily operation, it is necessary to keep the oil, no dry friction, normal oil pressure, and smooth oil path, so as to ensure the normal processing of the workpiece. At the same time, oil guns, oil cups, linoleum and other tools should also be kept clean.

Adhere to safe operating procedures

The protection of any equipment is inseparable from correct and safe operating procedures. Only by abiding by relevant regulations, not overloading the equipment, and eliminating unsafe factors in time can the machining center maintain a good processing state, prolong its service life, and effectively improve enterprise production. benefit.

Conclusion

There are many types of CNC machine tools, and the functions, structures and systems of various types of machine tools are also very different. Naturally, the maintenance and maintenance also vary from type to type. In addition to the above points, the specific use and maintenance must be combined with the provisions of the manual. This will make the device function better.

For more information about vmc 850 price,vmc 850 milling machine,vmc850 vertical machining center, we are glad to answer for you.