ຮູບແບບອີເມວຜິດພາດ

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

ຂ່າວ

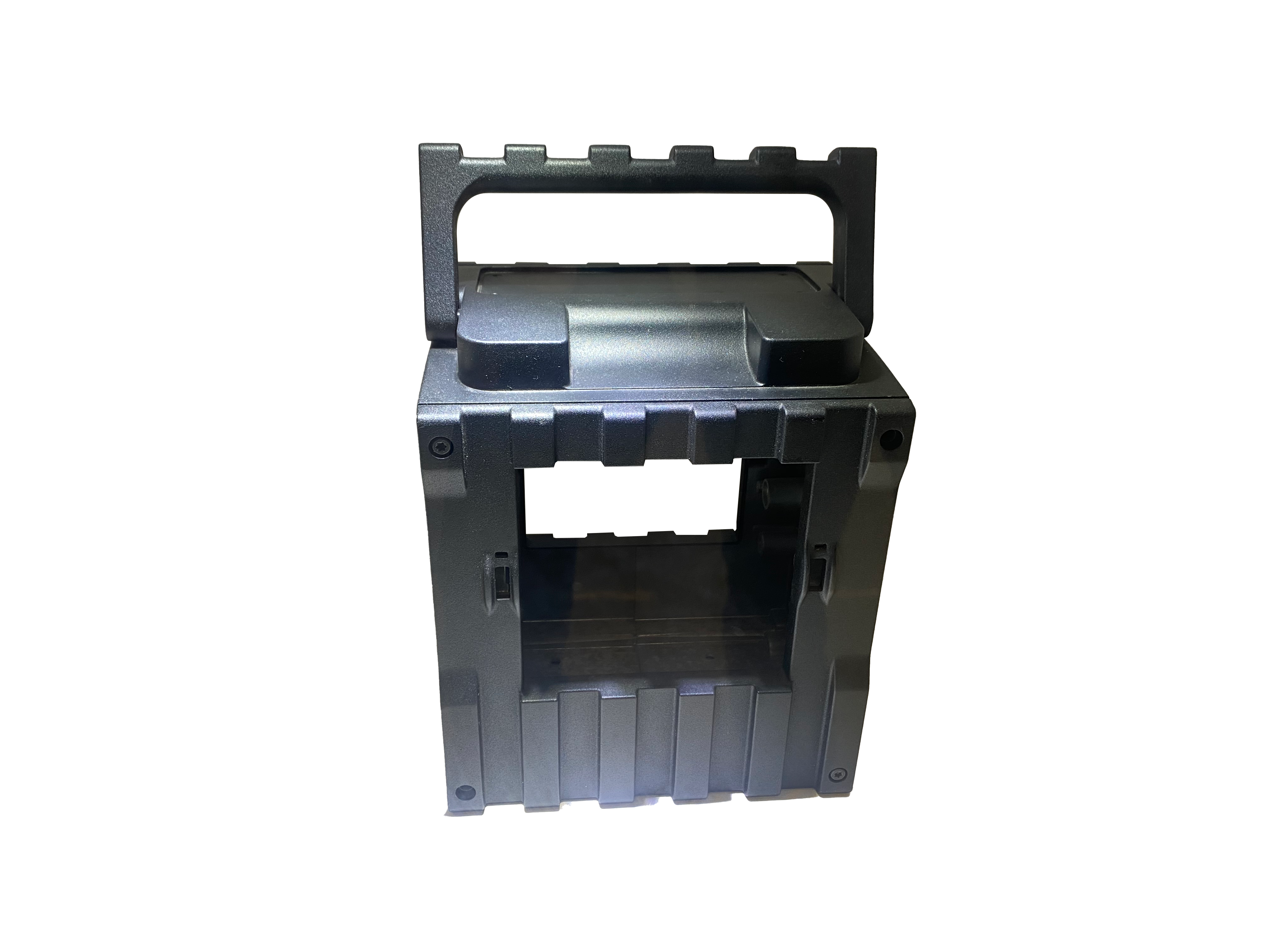

Electroplating Surface Treatment Process of Die Castings

Metal material plating is the whole process of spraying molten corrosion-resistant metal material to the metal surface with air compression or rare gas to produce a maintenance coating. When metal materials are plated, the plated surface raw materials are melted and atomized in a professional spray or spray gun, and sprayed onto the base material. This type of surface decoration is sometimes called metal material spray paint. Oxyacetylene flames are generally used, but other gases are sometimes used.

Preparation and application of electroplating for metal materials of castings:

When the coated iron wire is automatically fed according to the flame core, the iron wire is melted and additionally atomized and sprayed onto the base material by the compressed air flow. Basically, any metal material that can be made into iron wire can be plated in this way. Another spray gun uses powdered material to spew out the flames. The advantage of this method is that it can not only plate metallurgical materials, but also metalized ceramic polymer materials, metal oxides, and cemented carbide tools.

The surface layer before plating is prepared in advance: Since the fusion between the coating material obtained by metal plating and the base material is pure mechanical equipment fusion, the base material must be properly pre-treated. It is convenient to obtain excellent mechanical equipment integration. Regardless of which surface preparation method is used, the substrate surface must be cleaned and free of oil stains.

A common way to prepare the surface in advance is the sandblasting process.

Therefore, the grains of sand are sufficiently sharp to create a real matte surface, and for a cylindrical surface that can be rotated beside a lathe, a reasonable approach is to carve out a very thick external thread, and then gently extrude it with an extrusion knife. crest of teeth. An improvement that can be used in the plan view is to use a round grooving knife to cut a series of parallel face grooves, and then use a knurling knife to grab the land in the middle of each groove. If the plated surface is also to be processed, the substrate surface should be prepared in advance by rough machining or grooving to obtain a good preparation.

Process performance of casting construction:

- As far as possible, remove the inner side concave of the casting to make the mold design simple.

- Make the wall thickness of the castings as uniform as possible, and use ribs to reduce the wall thickness to prevent the castings from causing defects such as blow holes, shrinkage porosity, and deformation.

- Clean the deep holes and deep cavities on the castings as much as possible. Because the small, medium, and small cores are easy to bend and break. Inadequate filling and venting in deep cavities.

- The casting of the design plan should be conducive to mold release and core pulling.

Aluminum die casting is a unique forging method. Compared with other forging methods, its basic feature is that the shape memory alloy is filled and filled with the abrasive tool at a high speed and high pressure. The surging caused by the mold and the rapid cooling of the metal material and the damage to the abrasive tool caused by the high productivity make the castings unavoidable and cause many shortcomings. However, some disadvantages are not easy to damage the characteristics of the casting, so it is not easy to cause the casting waste, and some other defects will damage the characteristics of the casting and become scrap. Quality is the fate line of the company, the key support for improving the company's market competitiveness, and the key standard for improving the company's economic benefits. Therefore, improving the quality of castings, whether it is aimed at the economic development rights and interests of aluminum die-casting companies, or the social economy that reduces resource consumption benefits are all very beneficial.

Conclusion

For more information about types of die casting process,intensification pressure in die casting,pdc die casting machine, we are glad to answer for you.