ຮູບແບບອີເມວຜິດພາດ

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

ຂ່າວ

Vertical Milling Machine vs Horizontal Milling Machine

Although the design of vertical and horizontal milling machines is similar, their performance is very different. The best equipment for CNC milling parts depends on requirements, complexity, accuracy, and more factors. To determine which type of milling machine or machining center to choose, please check the complete difference between horizontal and vertical milling machines (vertical mill vs horizontal mill).

What is a horizontal milling machine?

A horizontal milling machine is a commonly used and most popular type of milling machine. The spindle is equipped with a horizontal direction and the cutter is installed on the spindle to rotate on the horizontal axis. This type of machine is ideal for developing certain types of slots and slots. The horizontal milling center comes with various customizations, such as multiple tools or rotating universal machines to cut various angles.

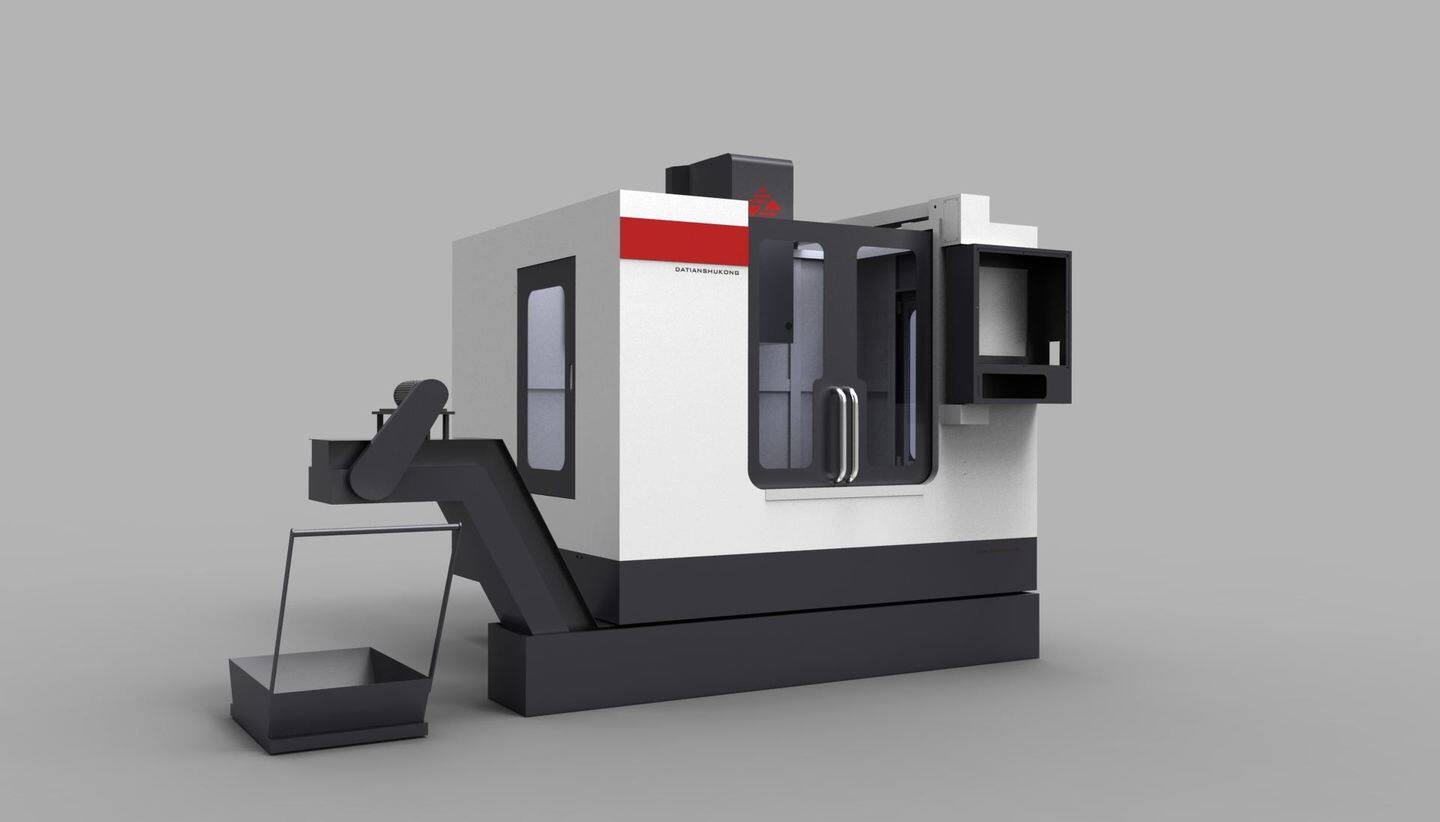

What is a vertical milling machine?

The vertical milling machine is characterized by a vertical spindle, which fixes the cutter on the workpiece and rotates it. On the vertical milling machine, the parts are fixed on the workbench, which moves laterally through the saddle movement, and can feed in the longitudinal, transverse, and vertical directions. It can even control the speed of the tool. Through high-speed rotation, the cutting edge cuts small pieces of the workpiece. When we need to carry out special types of operations, the vertical mill is the first choice. Vertical machine tools can be divided into turret milling machines and machine milling machines.

Difference between horizontal milling machine and vertical milling machine

The horizontal milling machine is usually composed of a base, column, spindle, extension, knee, saddle, workbench, yoke, shaft, vertical guide rail, horizontal guide rail, cutter, and knee joint lifting screw. Vertical milling cutters have the same basic components, and the most significant difference between them is the position of the tool spindle and the rotation of the tool.

- On the vertical milling machine, the spindle shaft is aligned vertically, while on the horizontal milling machine, the spindle shaft is placed horizontally.

- The accuracy of the vertical milling machine is higher than that of a horizontal milling machine.

- Generally speaking, the price of vertical mills is cheaper than that of horizontal mills.

- Surface finish. Horizontal milling machines provide a better surface finish.

- At the same tool speed and the same time, horizontal milling has a high material removal rate.

- The horizontal milling cutting speed is faster, and multiple cuts can be made at the same time.

- Horizontal milling machine is more customizable than a vertical milling machine. It can work with various tools.

- Horizontal milling machines can be used to process multiple faces, while vertical milling machines are usually used to process a single plane.

- Vertical machining centers usually use long and thin tools, while horizontal machine tools use short and thick tools to remove a large amount of material from the workpiece.

- Due to different cutting tools, horizontal milling machines can carry out deep and heavy cutting at high speed, while vertical milling machines usually only do general work, rather than drilling parts.

- Tools of life. The tool used for horizontal milling has a longer service life.

- Work area. Horizontal mills require a larger area.

- Vertical milling machines are generally lighter and less powerful than horizontal milling machines.

- Chip removal. Slices can be easily removed from a horizontal mill, but this cannot be done on a vertical mill.

- Horizontal milling is more suitable for large-scale production because of its higher speed and precision.

- Horizontal milling can handle larger and heavier materials without damaging the machine.